This regulator and cycle controller allows the whole vacuum operation, from start to finish, to be controlled, yielding a more consistent product process. After set-up, the chamber and vacuum system can automatically turn on the vacuum, watch for the preset vacuum level, then control the hold time at that vacuum level, then break the vacuum to allow the operator to remove and replace product. All this can happen without the operator watching. Your product becomes more consistent and your process more reliable.

Abbess Instruments currently offers three levels of Vacuum Cycle Controllers. Which is best for your system?

- Analog Vacuum Cycle Controller

- Digital Vacuum Cycle Controller

- Custom PC/GUI Vacuum Cycle Controller

Analog Vacuum Cycle Controller

This Controller is designed to be a part of our rugged bench top vacuum chambers in production or testing. Some of our customers find this to be a practical solution for using a vacuum chamber in a controlled process to dry products, and degas of parts, liquids, plastics, resins, and epoxies.

Includes:

- NEMA 13 Enclosure

- Vacuum and Vent solenoid Valves

- Heavy duty, Industrial Manual Control Switches

- LED indicators

- No digital gauge

- One singular set point

- Simple on/off control

Digital Vacuum Cycle Controller

Vacuum Cycle Controllers typically include:

- NEMA enclosure

- Integration with a Digital Pressure Gauge (such as a InstruTech CVM-201 shown bottom right)

- Vacuum Valves

- 1/2″ Vacuum and 1/2″ Vent, Solenoid Valves (can vary based off of requirements)

- Crouzet Digital Timer

- Manual Control Switches

- LED indicators

- Vacuum Set Point Indicator

Abbess Digital Gauge Vacuum Cycle Controllers add a dimension of ease of use, as well as clarity and precision to the monitoring and control of a vacuum cycle, whether used in process systems or testing applications. The digital gauge interface can be customized to read in user preference units of measure and enables the operator to easily modify setpoints for specified soak times. These systems can be purchased with a factory default vacuum cycle programmed or you can inform us of your cycle parameters and have them factory preset before shipment.

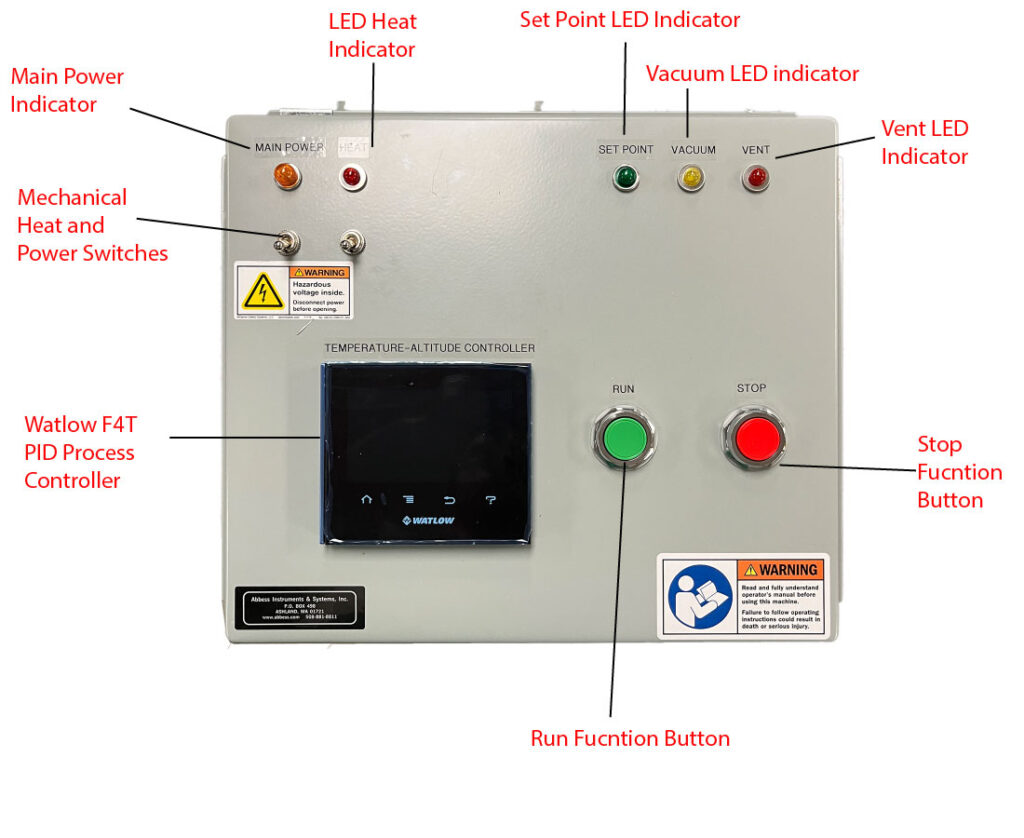

Below is what a VCC for a TVAC system looks like without a PC:

This is an example of one of our more complex VCC configurations that includes; turbo pump control, thermal controls, as well as full control over all other components.

Includes:

- NEMA enclosure

- Integration with a Digital Cold Cathode Pressure Gauge

- Vacuum Valves

- Electrically actuated HV Vent Valve – interlocked with turbo speed sensor.

- Crouzet Digital Timer

- Manual Control Switches

- LED indicators

- Vacuum Set Point Indicator

- Watlow F4T PID Controller

If you need to log data from your system, our VCC with a F4T is the best option!

Custom Touch Screen/PC Vacuum Cycle Controller

Customized PC and Touch Screen User interface.

Allows controlled Start/Stop control of vacuum system, process, sequence, position, pressure and/or temperature monitoring and setpoint control.

Includes:

- Custom User Interface design, requires custom sequence

programing option - Custom NEMA/Work station

- Serial/USB PC interface

- Data Acquisition Interface

- Data Logging and batch records

- Many data output options

- Integration with pumps, valves, and other controllers

- With Vacuum pump relay options

PANEL PC,

- 15″ CAPACITIVE TOUCHSCREEN,

- WINDOWS 10

- Provides I/O for RS485, USB, and rs232 devices

- DUAL LAN

- MINIMUM 32GB 2.5″ SSD

- MINIMUM 4GB SO-DIMM DDR4 2666

A PC Touch Screen Vacuum Cycle Controller is a custom built system. Each Touch Screen Controller is programmed for the customer’s specific procedure.

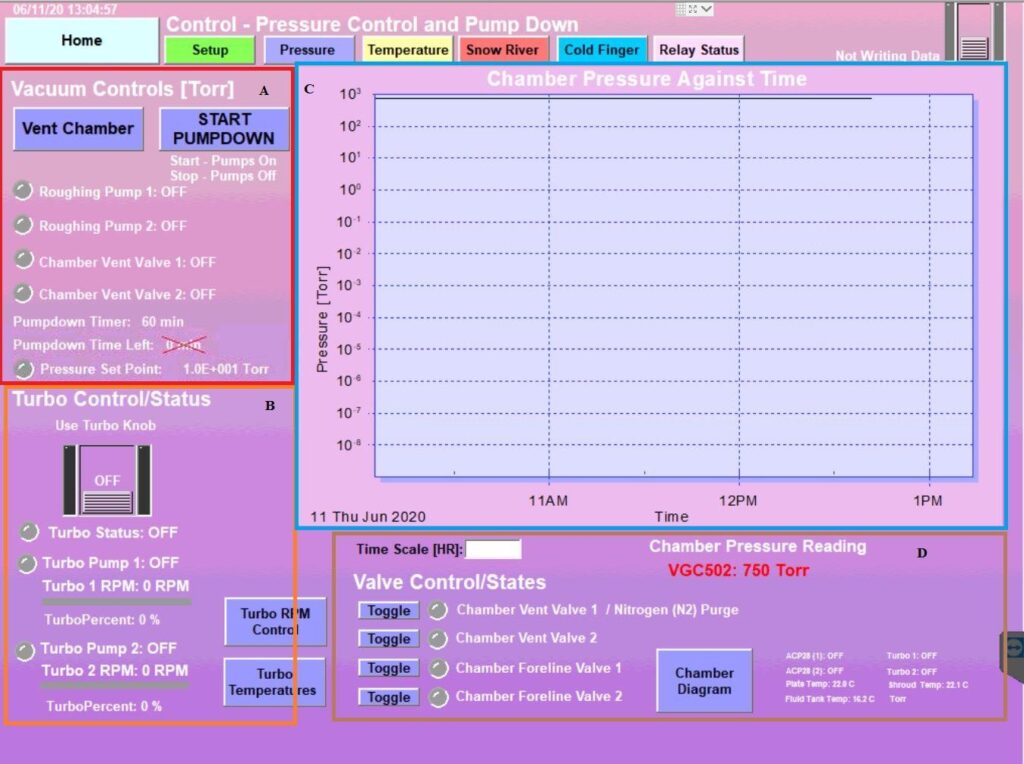

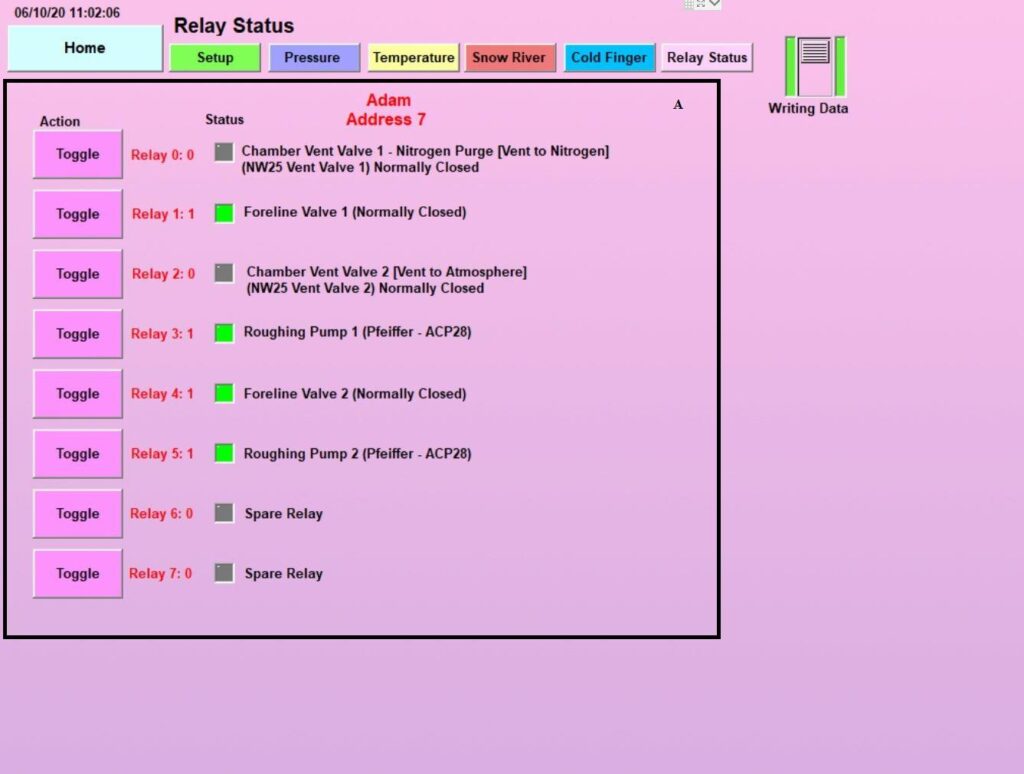

Below is an example of what the GUI will look like:

Here are just a few examples of systems we have built with a custom GUI/PC Controller!