Vacuum Chambers Systems | Cryogenic Products & Systems | Refrigeration Systems

Thermal Vacuum Chamber | Altitude & Atmosphere | Process Application & Mixing

Transportation Testing | Regolith Thermal Vacuum Systems |

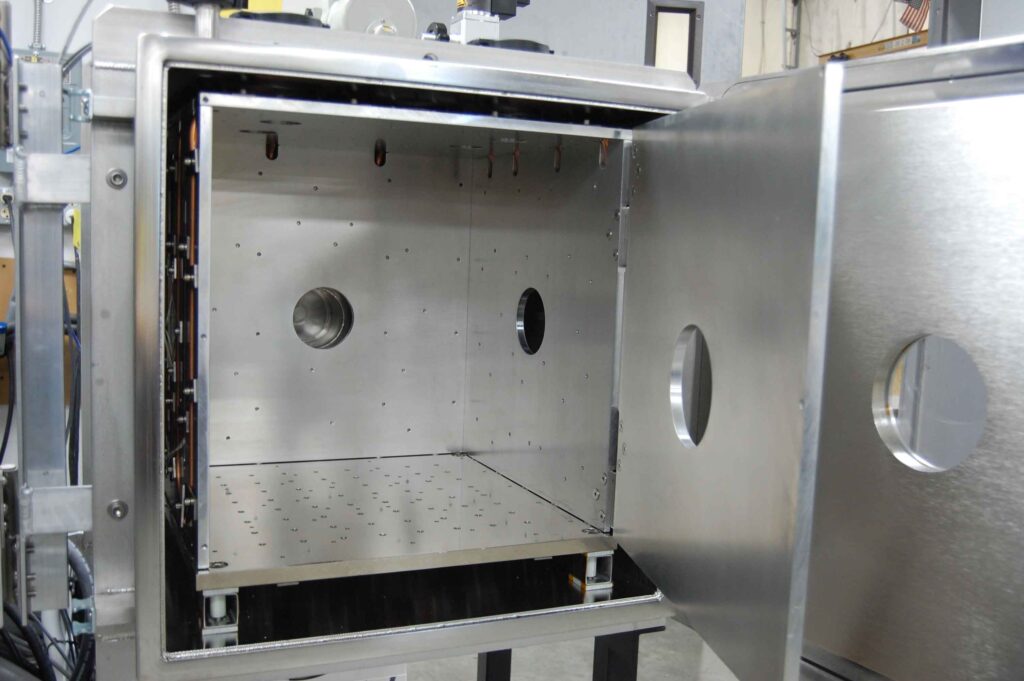

Thermal Vacuum Chamber Systems

Capable systems for demanding test and process application needs

Abbess Thermal Vacuum Chambers (TVAC) serve a broad array of end uses, from Satellite Testing and Altitude Flight & Deep Space Simulation to process applications such as vacuum and thermal assisted drying, molding and degassing and gas purge operations. Complex interaction with and monitoring of the Article Under Test can be facilitated by vacuum rated mechanical and electrical feedthrus for power, thermocouple and other sensor communication, device actuation. These working together with standard or customized Abbess Thermal Vacuum Control configurations serve to provide broadly useful tools for science and industry.

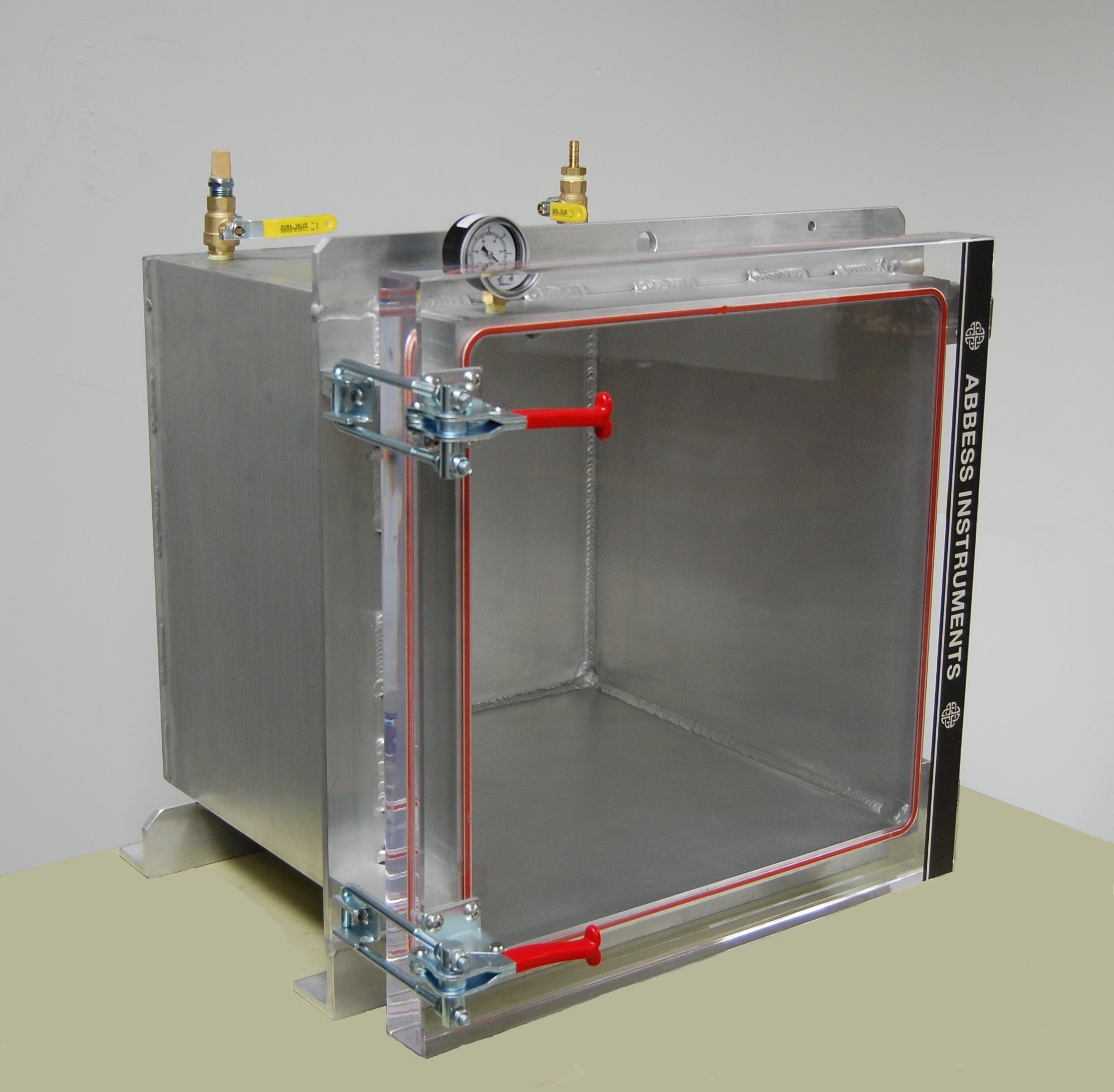

Vacuum Chambers for Science & Industry

Precise instruments for experimentation, and powerful tools for productivity

Abbess Instruments engineers and manufactures custom Vacuum Chambers for a broad range of user-defined systems, serving uses from scientific experimentation to industrial production. Abbess’s vertically integrated engineering sales, design and fabrication method positions the company to respond to stock order and custom fabrication requirements promptly and cost-effectively.

Component and Package leak testing, degassing, vacuum process methods, altitude flight, and deep space simulations; Abbess Vacuum Chambers serve as powerful and well-crafted tools in many sciences and industries.

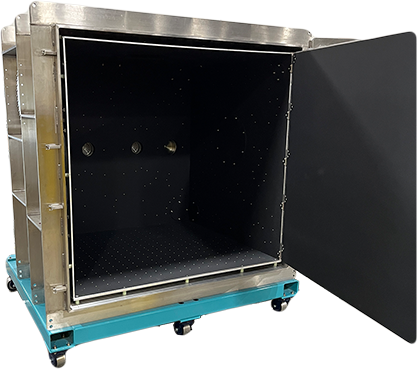

Regolith Thermal Vacuum Systems

Engineered To Each Customers Exact Specifications.

Abbess’ Regolith Thermal Vacuum Chamber systems (TVAC) serve to provide its end users with extreme customization when testing with Regolith. With our extensive experience with deep space simulation, coupled with our industry leading TVAC systems our engineers can create any test environment that your application may need. Accompanied by complex interaction and monitoring of the interaction between the Regolith and the test article. Tests can be facilitated by vacuum rated mechanical and electrical feedthroughs, thermal analysis, other sensor communication, and device actuation.

Our core team of engineers and technicians draw on extensive experience in the design and manufacturing of these systems to precisely replicate space conditions. With the use of our TVAC systems, we can recreate Lunar orbital conditions within our systems. This is just one of many examples of how Abbess’ Engineers are leading the charge in Regolith related testing.

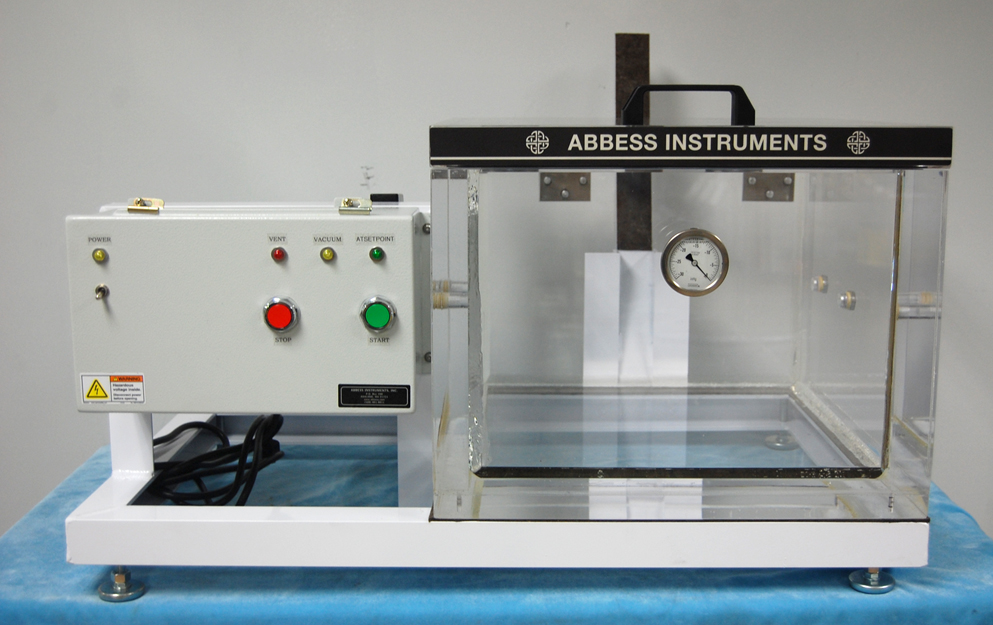

Altitude & Atmosphere

Proven powerful and practical tools for testing and experimentation

Abbess Altitude and Atmosphere Chambers are produced with an emphasis on careful coordination of the pumping equipment, the chamber properties and component and controls. Abbess has a highly evolved set of systems and tools specifically designed for recreating Altitude and Atmosphere conditions, Flight & Altitude Simulation, LEO, and Deep Space Test environments.

Thermal and Vacuum Chamber functionalities combine with profiling proportional control to give operators the tools they need to ramp both temperature and pressure and even customize gas mixtures for highly parallel chamber environments. Abbess Control Systems can be configured for basic function or customized for sophisticated and integrated tests, with customer specific PC/Touchscreen GUI and robust data-logging functionality.

Process Application & Mixing

Improving process and product with proven methods

Abbess has evolved a great number of useful vacuum chamber systems for process applications that involve degassing and mixing under vacuum and dispensing product. Where called for in a prescribed process, heat and gas purge can also become involved. Variable speed mixing is facilitated in scales ranging from bench top laboratory batches to 55 gallon drum containers. Systems can be configured with controls as simple as manual ball valve and pinch valve manipulation, or as complex as customized PC/GUI control of robotic dispensing with extensive data-logging for Quality Control.

Vacuum Infusion Systems working within the scale of Abbess 18″ and 24″ and 36″ cube chambers combine heating and vacuum degassing of infusing fluid with vacuum preparation of the product to be infused in an automated sequence.

Whether calling on one of our standard systems or customizing vacuum a system for integration into larger industrial or manufacturing process, Abbess responds with cost sensible.

Transportation Testing

Qualifying your product to ASTM Standards

Abbess abilities in the area of custom design and fabrication of Vacuum Chamber systems to simulate environments, as well as the production of robust, agile and capacious Thermal Systems, and our insight into Control and Data Configuration enable us to serve customers with transit testing requirements in a vast quantity of industries.

Our design team works with the end users engineers and product scientists to fully fathom the purpose and performance requirements of a given test regime. Then Abbess matches the tool to the test.

Refrigeration Systems

Up to the task of bringing down the temperature

Robust capacity and cost effective performance at demanding deep temperature Abbess brings a unique and innovative team approach to the challenges of temperature technology in a wide range of industries and applications. Our core team of engineers and technicians draws on extensive experience in the design and manufacture of systems for environmental simulation, experimental laboratory activities, and industrial process applications. Sensitive to end use concerns about capacity, ramp rate and temperature coherence, Abbess systems are sized right and provided with clear and agile controls.

Whether its development of a customized modular redundant refrigeration system for -80C cryo storage or the design and manufacture of robust and capacious deep temperature test systems for 6C/min profiling, Abbess is up to the task of bringing down the temperature.

Cryogenic Products & Systems

Robust accessories for any system requiring cryogenics

Abbess draws on more than a quarter century of experience in the design and fabrication of Deep Temperature Cryo Instruments and Systems, bringing a deep knowledge base in material properties and physics in the ultra low temp and cryo temperature context. Abbess designs and produces instruments of precise performance and robust service life.

Custom design and manufacture of Cold Fingers and Sample Fixtures, Cryostats, Cryo Storage and Cryo Trapping methodologies; Abbess has the firm command of cryo technology to answer challenges of practically any scale and complexity.